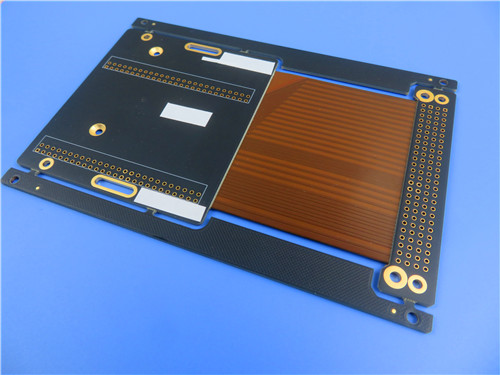

10-Layer Rigid-Flex PCB for Telemetry Systems

(FPC’s are custom-made products, the picture and parameters shown are just for reference)

Introducing Our 10-Layer Rigid-Flex PCB for Telemetry Systems

We are excited to present our advanced 10-layer rigid-flex printed circuit board (PCB), meticulously designed for telemetry systems. This PCB features a robust construction that combines a high-Tg FR-4 rigid board with a 50μm polyimide flexible board, ensuring excellent performance in high-density environments and complex mechanical scenarios.

Core Specification Parameters

| Specification | Details |

|---|---|

| Number of Layers | 10 layers |

| Rigid Material | High-Tg FR-4 (Tg ≥ 170℃) |

| Flexible Material | 50μm polyimide |

| Inner Layer Copper | 0.5oz (18μm) |

| Outer Layer Copper | 1oz (35μm) |

| Overall Thickness | 1.6mm, with controlled transitions between rigid and flexible sections based on design specifications |

| Surface Treatment | Electroless Nickel Immersion Gold (ENIG) |

| Solder Mask Color | Matte black, providing anti-glare and scratch resistance |

| Character Printing | Clear white silkscreen printing |

| Dimensions | 153.25mm × 87.66mm (single board size, processed according to design documents) |

Data sheet

| Size of Flexible PCB | 153.25 X 87.66mm |

| Number of Layers | 10 layers |

| Board Type | Rigid flex PCB |

| Board Thickness | 1.6mm |

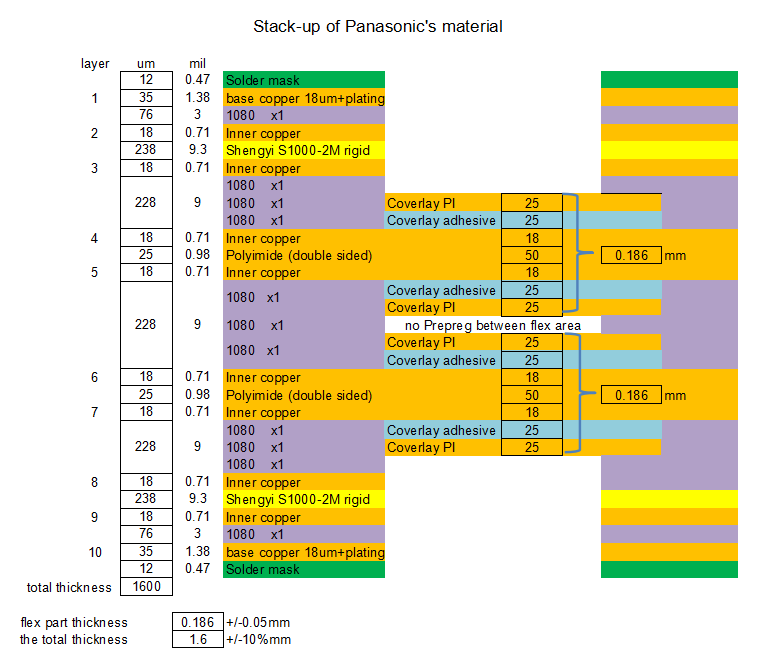

| Board Material | 1.6mm FR-4 / 0.2mm Polyimide |

| Board Material Supplier | Rigid (Shengyi) | Flex (Panasonic) |

| Tg Value of Board Material | 170℃ |

| PTH Cu thickness | ≥20 µm |

| Inner Iayer Cu thicknes | 35/18 µm |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Yellow coverlay / Matt Black solder mask |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | no |

| Stiffener Thickness | N/A |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 2 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

Special Process Requirements

1.Process Edge Design:

The width of the process edge is tailored to customer specifications, with designated text silk-screened on the outer edge.

Breakaway holes are included based on customer requirements.

2.Countersink Hole Processing:

Countersink holes are positioned according to customer design documents, adhering to IPC-6012 standards for diameter and countersink angle.

3.Serial Number Printing:

Unique serial numbers are printed in the format of Week/Year + Serial Number (e.g., 12/2025-01), with automatic incremental coding supported.

4.Alternative Scheme for Prepreg (PP) Layer:

The PCB includes three layers of prepreg material strategically placed between selected layers for enhanced performance.

Product Advantages

High Reliability: The combination of high-Tg FR-4 and the ENIG process makes this PCB suitable for high-temperature soldering and harsh operating environments.

Rigid-Flex Design: The flexible polyimide area supports dynamic bending, withstanding over 100,000 bending cycles, while the rigid areas provide essential mechanical support.

Precise Identification: The matte black solder mask with white characters balances aesthetics with functionality, while the serial number traceability system enhances quality control efficiency.

Flexible Adaptability: Supports alternative PP layer materials to optimize cost and performance based on specific project requirements.

Application Areas

Our 10-layer rigid-flex PCBs are ideal for a wide range of applications, including:

Industrial automation control modules

High-density communication equipment (e.g., 5G radio frequency modules)

Precision circuits in medical instruments

Vehicle-mounted electronics and aerospace electronic systems

Delivery Instructions

We are committed to delivering high-quality PCBs on time to meet your project needs. For more information or to discuss your requirements, please reach out to us!